At KBR Manufacturing, we engineer all types of plastic injection molds, assisting our clients in designing sophisticated plastic designs and addressing complex engineering challenges. Our experience developing hundreds of products for various molded plastic applications speaks for our credibility and trustworthiness.

Our hand-holding also includes assisting contract industrial design firms and in-house engineering departments of our clients with evaluating plastic part design. Accordingly, we help manufacturing companies enhance plastic performance and grow their productivity.

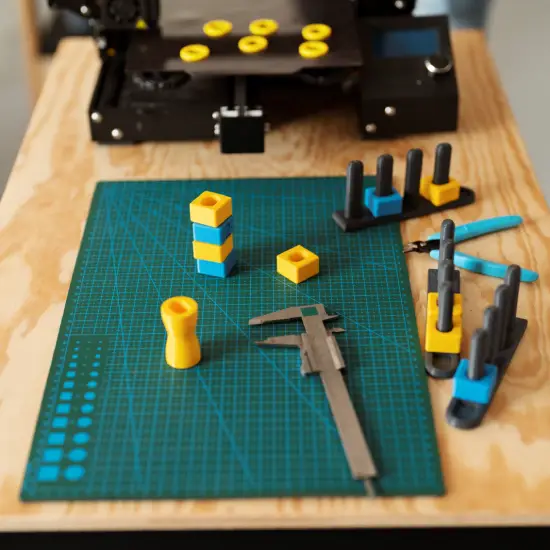

In addition to the above, our support includes managing tool design and building of low-volume simple geometry injection. Our expertise in injection molding helps us convert low-volume simple injections to automated high-volume injection molded parts comprising an intricate geometry. Over the years, we’ve also developed expertise in production, assembling, and automation.

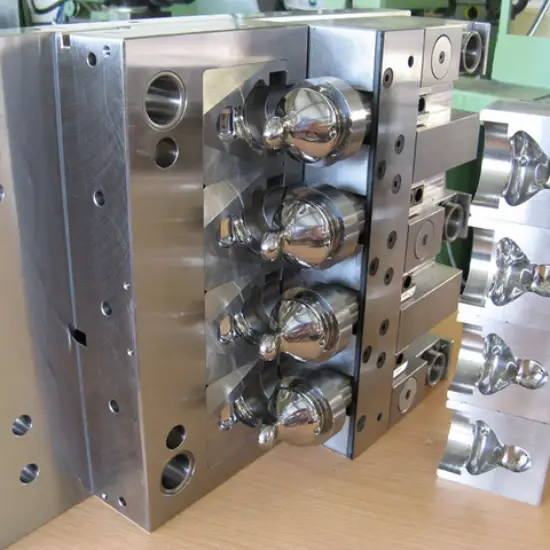

Our plastic injection molding services include melting raw plastic material in the injection unit and then injecting it rapidly into the mold under high pressure. We follow the standard plastic injection molding process that includes clamping, screw recovering, injecting, cooling, and ejection.

At KBR, we strive to deliver custom outcomes that help our clients derive the expected value. Some benefits of plastic injection we optimize include parts with complex geometries, automation to lower production costs, and efficient and repeatable manufacturing processes. Accordingly, we serve a range of industries, including transportation, automobile, manufacturing, construction, and more.

KBR Manufacturing specializes in plastic injection tooling that includes shaping and producing the metal components of a mold, shaping its final design and structure. We carefully plan every aspect of your project to perfectly craft every casting cavity and core box of the mold, per your specifications.

In addition to injection mold design and tooling, our expertise includes performing routine preventative maintenance procedures on all injection molds per the client’s specifications to ensure optimal performance.

KBR’s capabilities in this area include mechanical assembling, packaging, printing, kitting, machining, heat staking, and plastic component sonic welding. Our expertise also includes working on various plastic printing technologies to mark and decorate numerous plastic components. These include the following.

KBR’s support also includes providing custom plastic injection molded components to various OEM manufacturers. Our services and support in this area include everything from packaging and inventory management systems. Our assistance includes the following.

Elevate your operations by subscribing. From parts to precision, we’ll handle the rest!